Car engines, just like humans, need energy to move. In fact, the main function of the engine is to use the spark to convert the energy in the fuel into power to move. To create motion, this internal combustion produces tiny, airtight explosions.

While many of us think of an engine as a single unit, it’s actually made up of multiple different components that work together.

You may be familiar with the names of some of these car engine components, but it’s crucial to understand what they do and how they interact with other components in the engine.

Here is a complete engine parts guide for you to learn about cars and their engines and other parts before you start your business.

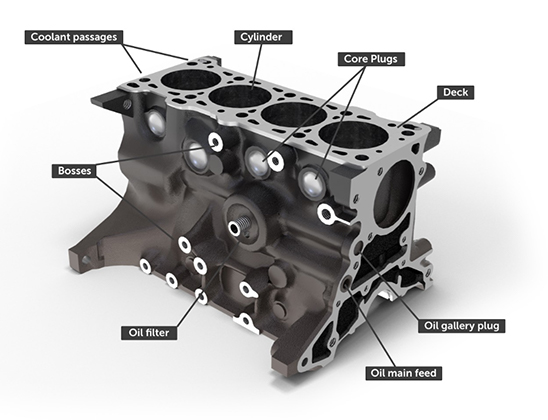

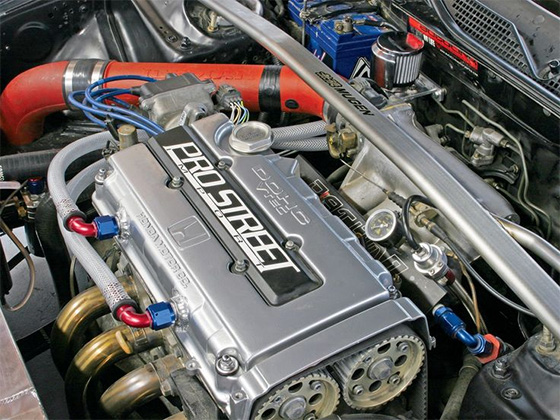

ENGINE BLOCK

Wondering what an engine block is? This is the basic core of the engine. It is usually composed of aluminum or iron and has many holes to keep the cylinders contained and allow water and oil flow lines to keep the engine cool and lubricated.

The water flow path is narrower than the oil flow path. The pistons, crankshaft, camshaft, and four to twelve cylinders (depending on the vehicle) are all mounted in a single line in the engine block, also known as inline, flat, or V.

The engine block, commonly called the cylinder block, includes all the basic components that make up the bottom end of the motor.

This is where the crankshaft rotates and where the piston moves up and down inside the cylinder bore, fueled by the combustion of fuel. It also holds the camshaft in certain engine types.

On current cars, older cars and trucks, it is usually composed of aluminum alloys. Its metal design provides its strength and ability to efficiently transfer heat from the combustion process to the inherent cooling system.

For the piston hole, the aluminum block usually has an iron sleeve pressed into it, or a specific hard plating is put into the hole after machining.

Cylinder bores, water cooling jackets, oil passages and crankcases were originally housed in metal blocks.

This so-called “water jacket” is a system of empty channels that circulates coolant in the engine block. The water jacket protects the pistons in the engine cylinders, usually four, six or eight in number.

Once the cylinder head is secured on top of the engine block, the pistons move up and down inside the cylinders and turn the crankshaft that drives the wheels.

The oil pan sits at the bottom of the engine block and acts as a reservoir for the oil pump to deliver oil to the oil passages and moving parts.

CYLINDER HEAD

The cylinder head is usually located on top of the engine block. Components such as intake and exhaust valves, springs and lifters, and combustion chambers are housed here.

This page describes the basic purpose and numerous designs of cylinder heads, as well as their failure causes and symptoms.

The cylinder head has openings that allow air and fuel to circulate within the cylinders while allowing exhaust gases to escape. A port or zone is an additional name for a path.

Coolant also passes through the cylinder head into the engine block, cooling the engine components. Cylinder heads use gaskets to prevent water or oil from leaking into the combustion chamber.

Flat Head Cylinder Head: The original cylinder head is a flat head. A flat cylinder head has no moving parts and is only used to protect the cylinder block. Since these cylinder heads do not allow effective air flow, the engine does not perform well.

Overhead Valve Cylinder Heads: These cylinder heads perform better than flat head cylinder heads. The camshaft is located above the valves in the overhead valve cylinder head. Push rods and valves on these heads are coupled together to create smooth airflow.

Overhead Cam Cylinder Heads: These cylinder heads are state-of-the-art. In an overhead cam cylinder head, the camshaft is mounted inside the cylinder head without pushrods. This improves airflow, which increases the efficiency of the engine.

The cylinder heads allow the engine to develop to its full potential by connecting to the intake and exhaust manifolds, which allow the rapid combustion of fuel and air, which pushes the engine’s pistons.

The intake manifold sends air into the head, where it combines with fuel to create exhaust that exits through the exhaust manifold.

To keep the engine running smoothly, the intake and exhaust valves that allow the gases of interest to enter and exit must open and close at precise time periods.

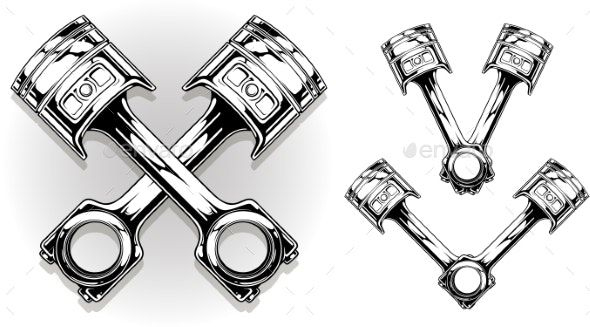

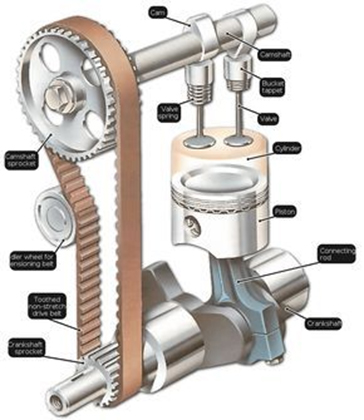

PISTON

A piston is a disc or short cylinder that fits tightly in an engine cylinder and pushes up and down a liquid or gas to create motion in an internal combustion engine or to transmit motion in a pump.

Pistons can be found in reciprocating engines, pumps, hydraulic and pneumatic cylinders, etc. It is the moving part encased in the cylinder and sealed with piston rings.

The purpose of the piston rod and/or connecting rod in an engine is to transfer force from the expanding gases in the cylinder to the crankshaft.

In a four-stroke car engine, the processes of intake, compression, combustion, and exhaust occur above the piston in the cylinder head, causing the piston to move up and down within the cylinder and the crankshaft to rotate.

This function is reversed in the pump, where force is transmitted from the crankshaft to the pistons to compress or expel fluid from the cylinders. In some engines, the pistons also act as valves by covering and uncovering the cylinder openings.

Engine components must be both durable and lightweight to be efficient. Therefore, automotive piston manufacturers usually make aluminum alloy pistons, while the piston rings are cast iron or steel.

OIL FILTER

The car’s oil filter also removes waste. It keeps your car’s engine running smoothly by trapping harmful particles, dirt and metal debris in the engine oil.

Without an oil filter, dangerous particles could get into the engine oil and cause damage. Filtering out the junk ensures that the engine oil stays cleaner for longer. Therefore, it is very important to choose a car oil filter manufacturer wisely.

FILTER

In a car, the intake manifold is the part of the engine that distributes airflow between the cylinders. The intake manifold typically houses the throttle valve and accompanying components.

The intake manifold in some V6 and V8 engines may be composed of many separate sections or components.

Intake air passes through the air filter, intake shroud (snorkel), throttle body, intake manifold supercharger, runners and cylinders. The throttle valve (valve body) regulates the flow of air to control engine speed.

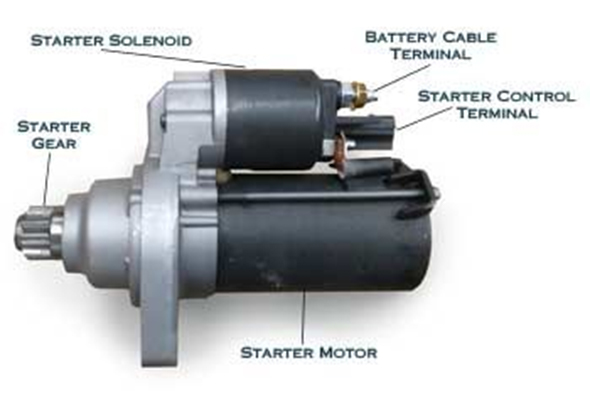

STARTER MOTOR

A starter motor is a small electric motor that starts a car’s engine when the key is turned on. For this to happen, the starter motor has to generate a lot of power to start the engine at such a high rate and draw fuel and air into the cylinders, compressing them at the same time.

The engine flips and then cranks when the car is started with the key. The most difficult part is getting the engine started, which requires a constant supply of air to the engine, which is achieved through suction.

Failing to flip is a typical problem with cars. This is mainly caused by a shortage of air, which prevents the fuel from burning.

CRANKSHAFT

- The crankshaft is the shaft driven by the crank system, which consists of a series of cranks and crankpins to which the engine’s connecting rods are attached. It is a mechanical device that converts reciprocating motion into rotary motion.The main function of this connecting rod is to absorb the reciprocating motion of the piston and transmit it to the crankshaft. When the connecting rod moves the crankshaft, it converts the motion into rotational motion and turns the flywheel, which continues to move the vehicle’s wheels.

A reciprocating piston engine without a crank cannot transmit the reciprocating motion of the pistons to the drive shaft.

Without a crankshaft, a reciprocating engine cannot propel a vehicle.

The power cycle is followed by various engines with different numbers of crankshaft speeds. For example, a two-stroke engine completes its power cycle after one revolution of the crankshaft, while a four-stroke engine completes its power cycle after two revolutions of the crankshaft.

The main components of a car engine crankshaft are:

crank pin

major periodicals

crank web

counterweight

Thrust washer

Oil circuit and oil seal

Flywheel mounting flange

CAMSHAFT

A camshaft is a rotating part consisting of a basic rod or shaft, usually made of metal, with a “cam cam” that converts a rotating motion into a reciprocating motion.

As the shaft rotates, the cam allows it to act on the valve or switch according to its shape, the rate of rotation determines the rate of action.

Camshafts were used as speed controllers in internal combustion engines to operate intake and exhaust valves, as well as in manually controlled ignition systems and early electric motors.

Camshafts in cars are made of steel or cast iron and play an important role in determining the RPM range of the engine’s powerband.

A camshaft is a rod that rotates and slides towards the machine in order to convert the rotary motion into linear motion. This displacement of motion is accomplished by the camshaft getting closer and closer to the plane of rotation as the machine pushes against it.

The camshaft on an internal combustion heat engine is a mechanism that controls the intake and exhaust of fuel. It consists of many radial cams, each of which replaces an intake or exhaust valve.

The camshaft is connected to the crankshaft by a belt, chain or gears. This ensures that the timing of the valve is always proportional to the speed of the piston.

CRANKCASE

In a reciprocating internal combustion engine, the crankcase houses the crankshaft.

Crankcase compression is common in two-stroke engines, which means the fuel/air mixture passes through the crankcase before entering the cylinders. In this engine design, the crankcase has no oil sump.

In a four-stroke engine, most of the engine’s oil is retained in the crankcase, and four-stroke engines usually have an oil pan at the bottom of the crankcase.

In a four-stroke engine, the fuel/air combination does not flow into the crankcase, but a small amount of exhaust gas from the combustion chamber often enters as “blowby”.

In most engines the crankcase forms the lower half of the main bearing journals (the bearing caps contain the other half), but in some engines the crankcase completely surrounds the main bearing journals.

CONNECTING ROD

Connecting rods connect the pistons to the crankshaft of a piston engine. link. Used in conjunction with the crank to convert the reciprocating motion of the piston into rotation of the crankshaft.

It allows rotation on the piston end and rotation on the shaft end in the configuration most typical in internal combustion engines.

The mechanical connection used by the waterwheel converts the rotary motion of the waterwheel into reciprocating motion, and is the forerunner of the connecting rod.

ENGINE VALVE

Engine valves are structural components of an intrinsic internal combustion engine that allow or restrict the flow of fluids or gases into and out of the combustion chamber or cylinders throughout their activity.

They function like many other types of valves in that they prevent or allow flow, but they are simply mechanical devices that interact with other engine components (such as rocker arms) to open and close in the proper sequence and at the proper time.

The term engine valve can also refer to a type of check valve used in automotive emission control and exhaust gas recirculation systems for air injection. This page will not discuss this type of engine valve.

Engine valves are found in a variety of internal combustion engines, including those that run on gasoline, diesel, kerosene, natural gas (LNG), or propane (LP). The number of cylinders, the combustion chambers in which power is generated through the ignition of fuel, varies by engine type.

An overhead valve (OHV) engine is a piston engine with the valves placed above the combustion chamber in the cylinder head. Early flathead engines had the valves located under the combustion chambers in the engine block, which was the Cavalier.

In a typical OHV engine, the camshaft is located in the engine block. The motion of the camshaft is transmitted to the valves at the top of the engine via pushrods and rocker arms.

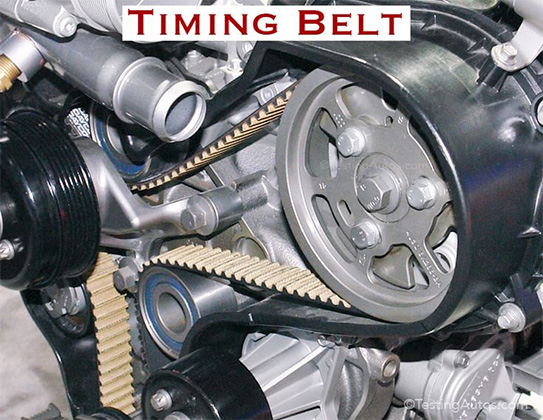

TIMING BELT

The timing belt, also known as the cam belt, is critical to keeping the internal combustion engine running. The timing belt’s job is to synchronize the rotation of the crankshaft and camshaft, and if the two are in sync, the vehicle’s pistons and valves will operate normally.

This is critical because the vehicle’s valves control the intake and exhaust of the fuel/air mixture and push the piston down when the fuel ignites in the combustion chamber. So whether you drive a brand new car or an older vehicle, it’s important to make sure your timing belt is in good running order.

The timing belt is placed in front of the vehicle’s engine. It consists of a tough rubbery substance with nylon-reinforced cords.

Therefore, the service life of the timing belt can be extended.

The timing belt is under a lot of stress as it moves inside the engine, and as a result, it wears out quickly. Therefore, the timing belt needs to be replaced regularly according to any car oil filter manufacturer’s regulations.

If the timing belt is worn and not repaired, it can cause a lot of costly damage to the engine.

The cost of a timing belt replacement is determined by the number of hours spent on the replacement order. After all, certain components, such as the timing belt, are more inaccessible in certain vehicles.

Since economy cars with small engines are easy to disassemble, the work required should be cheaper.

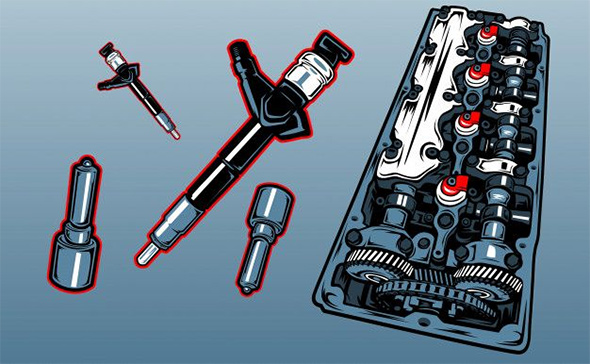

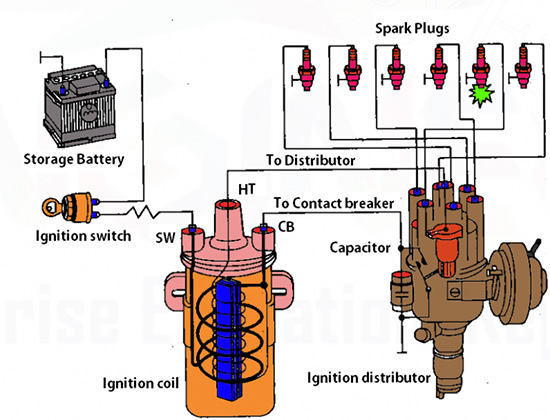

IGNITION

The ignition mechanism must ignite the air and fuel mixture in the cylinder at the proper time. Finally, an electrical system is needed to power the engine’s accessories, as well as operate the starter motor that starts the engine.

The element that generates this high voltage is a coil. When the distributor contacts the breaker point open, it is an electromagnetic device that converts low tension (LT) current from the battery to high voltage (HT) current.

The distributor is a metal bowl with a spindle, usually actuated by a valve, but can also be controlled by a crankshaft.

The contact breaker points, the rotor arms and the device for changing the ignition timing are all housed in the drum. It also attaches the dispenser cap.

SPARK PLUG

A spark plug, also known as a spark plug, is a device with two electrodes that fits into the cylinder head of an inherently ignited engine.

It is separated by an air gap through which electricity from the high-voltage ignition system exits, creating a spark that ignites the air-fuel mixture.

The electrodes must withstand high temperatures, and the insulator between them must be able to withstand high temperatures as well as electrical stress of several thousand volts. The energy of the spark is affected by the length of the spark gap, and the working temperature is affected by the shape of the insulator.

When the temperature is too low, carbonization of the gap and short circuit occur; when the temperature is too high, foreboding may occur.

If the voltage supplied to the plug is high enough, electricity is delivered through the spark plug, jumping over the gap at the firing end of the plug.

The gasoline/air mixture in the combustion chamber is ignited by this electric spark. The plug is connected to the high voltage generated by the ignition coil or magneto.

A spark plug is an electrical device that inserts into the cylinder head of some internal combustion engines and uses an electric spark to ignite compressed aerosol gasoline.

The spark plug has an insulated center electrode, is connected to an external ignition coil or magneto circuit by a highly insulated wire, creates a spark gap within the cylinder, and has a ground terminal on the base of the plug.

CONCLUSION

With so many systems performing so many functions at such high speeds, parts can start to wear out over time, causing the car to behave differently.

Although car engines may seem complex, their purpose is simple: to propel the car forward. With so many components working together to generate motion, it’s vital that your vehicle is properly maintained to last its life.

Oil changes at recommended intervals, flushing fluids, and changing belts and hoses are all excellent ways to help avoid the unpleasant situation of engine failure

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.