The automotive wheels market is projected to grow at a CAGR of 5.52% through 2025. Important aspects driving the growth of the global wheels market are the frequent product launches by regional and general automotive wheel manufacturers. Several manufacturers are adopting innovative approaches to increase the market share of their products.

The success of the new wheel product is expected to accelerate the business growth of the manufacturer. This blog will help auto parts manufacturers understand all the new wheel products available in the market and how they will benefit their applications.

WHEEL &RIM?

The words “wheel” and “rim” are often used as terms with almost the same meaning, but technically, they are not the same.

WHEEL

A wheel is the primitive round part of a car or motorcycle that spins to move the car forward. The wheels are placed vertically under the car, which not only aids in mobility, but also provides support for the vehicle to carry heavy loads.

These auto parts mainly consist of spokes, discs and rims. Spokes are the rods that start from the center disc and extend up to the outer rim of the wheel. The disc is what connects the rim to the hub. The rim is the part of the wheel on the outer rim of the wheel.

Some other parts of the wheel include a center hole and a circular space behind the center of the wheel that serves as a hole for connecting different parts of the vehicle’s accessories.

RIM

The rim of a wheel is just the outer rim, or the circumference of the wheel where the rubber pads are molded. Aside from diameter, one thing to consider when sizing a wheel is the width of the rim. The car rim design of the wheel is an important part as it enables the correct fit between the wheel and the tire.

RELATIONSHIP

The rim plays an important role in determining the size of the overall wheel. The primary function of the rim is to support and seal the tire into the wheel. The rim helps keep the air inside the tubeless tire and ensures it fits properly. The rim is an essential part of the wheel, without it the wheel would lose its shape.

AFTERMARKET WHEEL& OEM WHEEL

OEM WHEEL

OEM is an acronym for Original Equipment Manufacturer, and knowing an OEM and what they can do can make a big difference when choosing a brand new set of wheels. OEM wheels are wheels made by your vehicle’s original company and are exact replicas of the original wheels that came with the car.

Where the wheel is not produced directly by the original vehicle manufacturer, it is manufactured by an independent automotive component supplier with the support and collaboration of the original wheel rim manufacturer. These wheels are guaranteed to be in full compliance with the company’s original factory wheels in terms of size, performance and aesthetics.

AFTERMARKT WHEEL

Aftermarket wheels are wheels made by independent automotive wheel manufacturers to fit a wide variety of vehicles perfectly. Any wheel that is not made by the original manufacturer of the vehicle company and is made by a company not related to the automaker is considered an aftermarket wheel.

Aftermarket wheel manufacturers aren’t actually trying to copy or steal the original wheel’s design, which can be easily seen in the different looks of aftermarket wheels. The main benefit of using aftermarket wheels compared to OEM wheels is the difference in overall car wheel cost. Most aftermarket wheels offer complete safety and meet performance specifications that OEM wheel manufacturers also adhere to.

Car wheel manufacturers design wheels based on several aspects that are unique to a car, such as the car’s weight, handling, and other important factors. Aftermarket wheel suppliers often specialize in making wheels that are close to the OEM version, but not quite the same.

RIM

Rims are available in a variety of materials, all of which offer specific advantages over the others. In the early days, the rims were made of wooden materials, and then due to the roughness of the road surface, metal replaced it. The rim manufacturing process has changed a lot since then. Some of the materials used to make rims include:

1.ALLOY WHEEL

ALLOY WHEEL?

Alloy wheels are wheels made of aluminum and magnesium alloys to meet the requirements of the automotive industry. Aluminum or magnesium alloys are lightweight and as strong as steel wheels. They also provide better heat transfer, and the alloy wheels look very attractive.

PRICE-ALLOY RIM

While alloy rims are considerably more expensive than steel rims, car wheel alloys can start at $50 and can go as high as $500 depending on the size and quality of the material used.

ADVANTAGE

1. Attractive appearance

The fact that alloy wheels look more attractive than steel wheels cannot be ignored. Several automotive alloy wheel manufacturers have focused on cosmetic upgrades and improving the visual impact of their wheels, which has helped them increase sales.

2. Good thermal conductivity

Alloys are able to dissipate heat better than other materials used to make rims, and they provide good braking performance, reducing the risk of brake failure.

3. Good performance

Since auto wheel alloy dealers are always looking for better performing wheels, they choose alloy wheels because they help reduce unsprung weight and allow the suspension to follow the terrain with ease. In addition, there are significant improvements in steering handling.

4. Good fuel economy

Alloy wheels are light in weight which allows them to improve fuel efficiency to a great extent.

5. Better braking

Alloy wheels provide better braking as it reduces wheel hop, which provides better traction.

SHORTCOMING

While alloy wheels from a reliable car wheel supplier offer advantages when it comes to the look and performance of your car, they are not as durable as steel wheels. Additionally, alloy wheels are more expensive to produce and repair than steel wheels.

2.STEEL WHEEL

STEEL WHEEL

The name steel wheels is self-explanatory, which means the wheels are made of steel. Steel wheels have been around for a long time and are known for their toughness and durability. For this reason, most city cars and hardcore SUVs use steel wheels. Automotive wheel manufacturers often use steel wheels as a cost-effective alternative to alloy wheels.

PRICE-STEEL WHEEL

Steel wheels can cost anywhere from $30 to $100, depending on the size of the car’s wheels.

ADVANTAGE

steel wheel price

Steel wheels are manufactured by stamping the wheel into a round shape, which means production costs are much lower than alloy wheels.

2. Durability

Steel wheels are much stronger than alloy wheels, which is why auto parts manufacturers find them suitable for rugged SUVs.

3. Easy maintenance

Steel wheels are more malleable than most, which makes them easy to repair by simply hammering the bent section back into shape.

SHORTCOMING

1. Steel wheel weight

Steel wheels are heavy, which adds weight to an unsprung car, and with the extra weight, the car’s suspension takes a hit after working for a while. However, some car companies use the weight of steel wheels to provide better traction and maneuverability.

2. Corrosion

Steel wheels don’t work well in wet environments because they rust easily. However, with modern paint techniques, steel wheels can resist corrosion to a certain extent.

3.CHROME WHEEL

CHROME WHEEL

There is a common misconception that chrome wheels are made of chrome, but the truth is that they are just alloy or steel wheels with a chrome coating. Adding a layer of chrome doesn’t do the wheel any favors, it just enhances its aesthetics. In addition, it provides excellent wheel oxidation protection

CHROME WHEEL

Chrome wheels can run you at least $150 to $300, depending on rim and wheel size.

ADVANTAGE

The chrome finish gives the wheels a mirror-like sheen, adding to the overall aesthetic of the car. It makes the wheels very strong and resistant to the elements. The chrome wheels are metal plated to make them stronger.

SHORTCOMING

Chrome plating a wheel requires adding several layers of metal to achieve the desired finish, which adds weight to the wheel. This could negate the performance advantage of lightweight wheels over heavyweight wheels. If the chrome plating is not done properly, the metal layer may start to wear away, increasing repair costs.

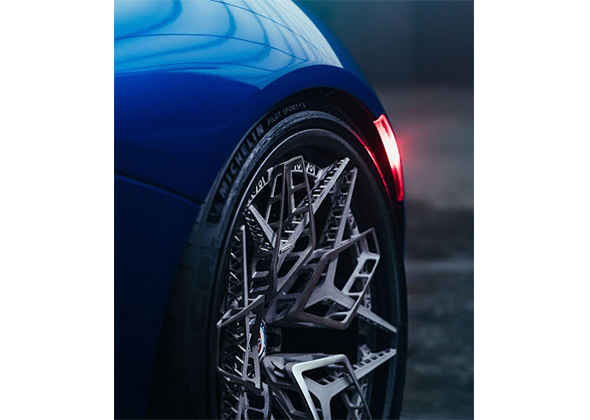

4.FIBER WHEEL

CARBON FIBER WHEEL?

Carbon fiber wheels are wheels made of carbon fiber that help reduce moment of inertia and wheel weight. This feature helps to improve the acceleration of the car.

PRICE-CARBON FIBER RIM

A pair of carbon fiber rims can run you upwards of $10,000, which is why they’re mostly found in high-end sports cars that require better acceleration and shorter braking distances.

ADVANTAGE

1. Lightweight

Manufacturers of automotive wheels utilize lightweight carbon fiber to improve vehicle performance.

2. Select range

Thanks to the lightweight carbon fiber, manufacturers can develop a variety of designs to meet the requirements of all car companies.

3. Improve aesthetics

Simply put, a set of carbon fiber wheels give the car a good looking look.

SHORTCOMING

1. Expensive

Although carbon fiber rims give the car better performance and offer several other benefits, their cost is too high for an economy car.

2. difference

Lamination differences reduce the radial and lateral stiffness of the wheel, causing the wheel to become unbalanced.

HOW TO MAKE THE RIM?

Car rims are the simplest components in a car, but large rim manufacturing companies are always looking for the latest manufacturing techniques and developing the strongest and lightest rim materials to improve the performance of the wheel and the car. The wheels of a car have enormous technical and aesthetic responsibilities that simply should not be neglected.

FORGED WHEEL

FORGED WHEEL

Forged wheels are made from a large square piece of solid metal that is heated to extreme temperatures and pressurized to form circular shares. Unlike cast wheels, forged wheels may have an irregular surface and may require machining to smooth them out. The heat cycles that make forged wheels help them become stronger due to grain refinement.

The consistent forging of the wheel gives it greater structural integrity and requires less material than cast wheels. However, the process of making forged wheels is more expensive than making cast wheels.

The thicker parts of the wheel that need to move material use the hot forging method. To forge the complex components of a wheel, rim builders need multiple operations to achieve the perfect shape, and each additional step adds additional expense to making the wheel.

The hot forging process starts with a large block of aluminum, which is heated until it melts, and then placed in a forging press. Next, it is struck or compressed using a hydraulic press to create a molding die. Then the rim builder pulls out a cooling part that looks like a mold shape.

Forging presses generate incredible force in order to move material in and out of dies. The mechanical press used to shape the wheels can be three stories high, with half of the machine underground. A manufacturing unit is then developed around the printing press.

The advantage of using a forged part is that it produces a very smooth grain structure. The material formed as a result of forging has long, continuous grains on it. Therefore, forged wheels are very strong and lightweight.

CASTING WHEEL

The casting wheel manufacturing process involves heating a large block of aluminum until it melts into a liquid state. Using a vacuum, auto parts manufacturers pour molten metal into molds and shape it into its final shape. After cooling, the castings are trimmed and baked to perfection. Although the casting process is quick and economical, it does result in a material that is weaker than forged wheels.

Molten aluminum is poured or vacuumed into a mold that is molded into the shape of a wheel of various sizes, this is the casting process. Positive pressure is used to accelerate the flow of the aluminum alloy into the mold, producing a product with a higher density than gravity cast wheels. Then give it time to cool before making small modifications like drilling and trimming.

IMPORTANT ITMES

1.CUSTOMER-TPYE

Steel wheels are your choice if you want to serve the adventurer who likes to drive into nature and challenge their vehicles in rough terrain. Steel rim materials are great for those who like to drive off-road as they are the strongest of the many rim materials.

On the other hand, if your customer base leans more towards the look of the car, you can opt for alloy wheels. If you serve customers who live in wet or harsh environments, you should consider alloy wheels, as steel wheels are prone to rust, especially when exposed to moisture.

2.SERVICE-TYPE

As an automotive rim manufacturer, the type of vehicle you service is an important aspect of choosing the right wheels. Racing wheels need to be strong yet lightweight, so you can opt for carbon fiber rims that provide high acceleration and reduced braking distances. Truck rims and motorcycle wheels, on the other hand, require standard specifications that steel and alloy wheels can achieve.

3.AFTER-SALE&OEM

Aftermarket or OEM wheels are other important factors to consider when choosing the right wheels for your customers. Aftermarket wheels make an attractive modification to a car and help enhance the overall look of the car. However, aftermarket wheels do not provide the same performance as OEM wheels. OEM wheels are a safe bet when it comes to vehicle performance and durability.

4.BURGET&QUALITY

As an automotive rim company, the most important consideration is the budget for the wheels. The cost of the wheels should be worth the specs and performance the wheels offer. The budget for building a wheel will determine the quality and performance level of the finished product.

If you are on a tight budget, you can opt for steel wheels as they are usually less expensive than alloy and chrome wheels. It’s also very cost-effective to replace or repair drums.

- DELIVERY-TIME

The time it takes to design, manufacture and deliver a wheel is another important factor in helping determine which wheels are right for your business. Steel wheels require no extra effort or time to manufacture, which is why they are the most common choice for car companies. If you choose to select a reputable OEM or aftermarket wheel builder for your business to deliver regular orders on time and prioritize rush orders, then

Delivery time may not always be a determining factor. There is usually a time frame for delivering a car, and the lead time for building the wheels has to be tight.

CONCLUSION

Wheels are the foundation of any vehicle as they support it in a number of ways. The entire weight of the car is supported by the four wheels, and the acceleration and braking system of the car also depends on the specifications of the wheels. Depending on your budget and target audience, you can choose between steel, alloy, chrome and carbon fiber wheels.

You can contact reputable auto parts suppliers to help you choose the right wheels for your business. Some custom wheel manufacturers also offer excellent customization services that help in meeting customer requirements.